PLATFORMS & ROBOTICS

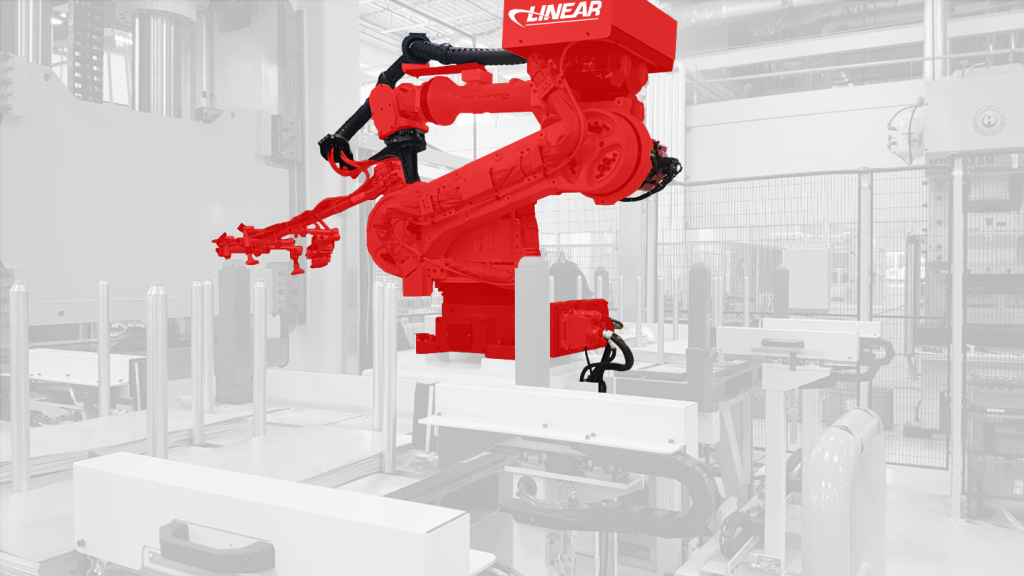

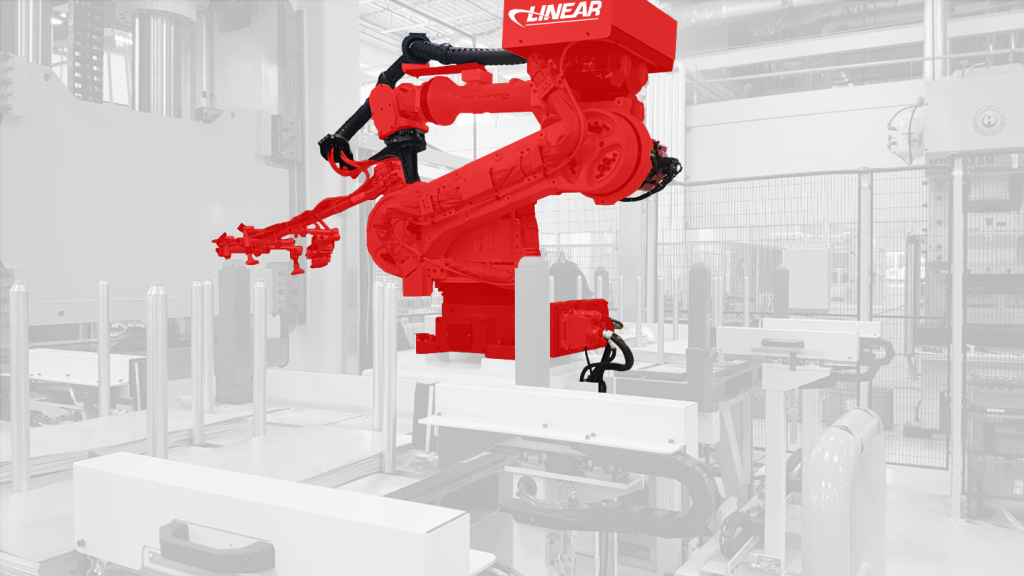

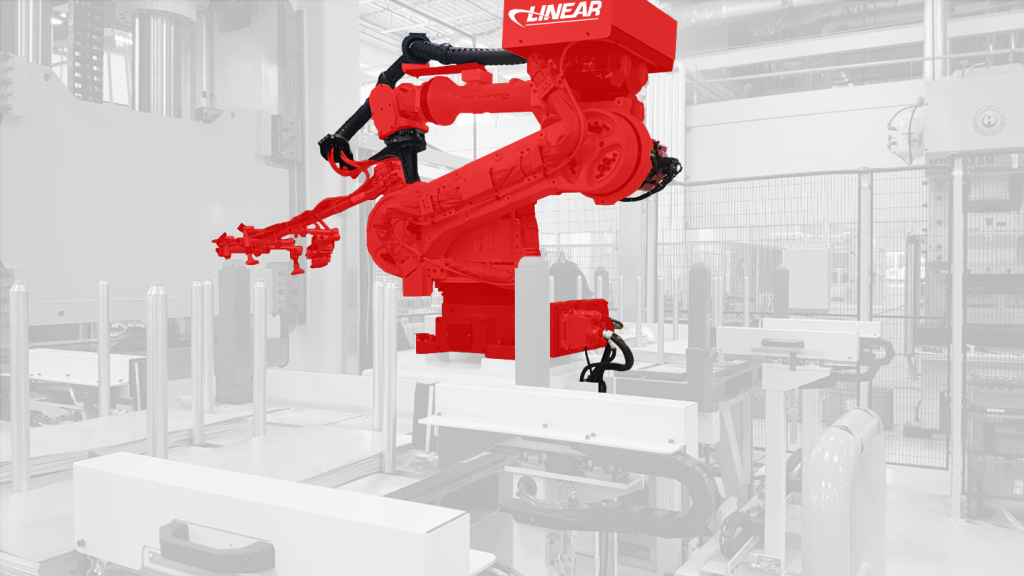

Linear Automation offers a range of robotic automation solutions and transfer systems tailored to meet our clients’ specific needs in metal forming automation. Our strong partnerships with leading robot manufacturers such as ABB, FANUC, Yaskawa Motoman, KUKA, and Kawasaki Robotics, combined with compatibility across various control system platforms, ensure that we deliver solutions that align with your equipment standards. Whether you need advanced robotic systems or integrated transfer systems, we are dedicated to fulfilling your automation requirements while enhancing the efficiency and performance of your metal forming processes.

PLATFORMS & ROBOTICS

Linear provides diverse robotic automation solutions tailored to fulfill our clients’ needs. With partnerships established with leading robot manufacturers like ABB, FANUC, Yaskawa Motoman, KUKA, and Kawasaki Robotics, alongside compatibility with various control system platforms, we ensure that our customers’ automation needs are met while adhering to their equipment standards.

PLATFORMS & ROBOTICS

Linear provides diverse robotic automation solutions tailored to fulfill our clients’ needs. With partnerships established with leading robot manufacturers like ABB, FANUC, Yaskawa Motoman, KUKA, and Kawasaki Robotics, alongside compatibility with various control system platforms, we ensure that our customers’ automation needs are met while adhering to their equipment standards.

UPGRADES & RETROFITS

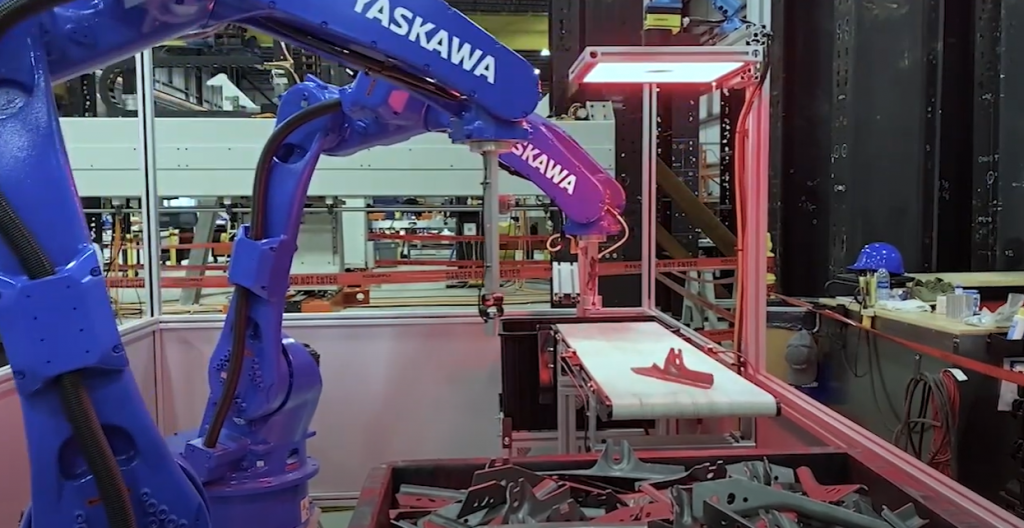

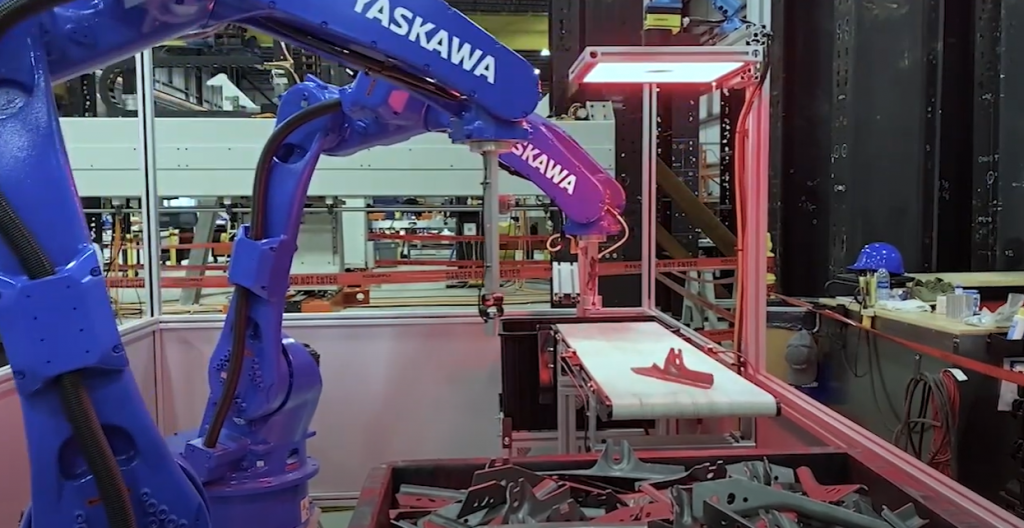

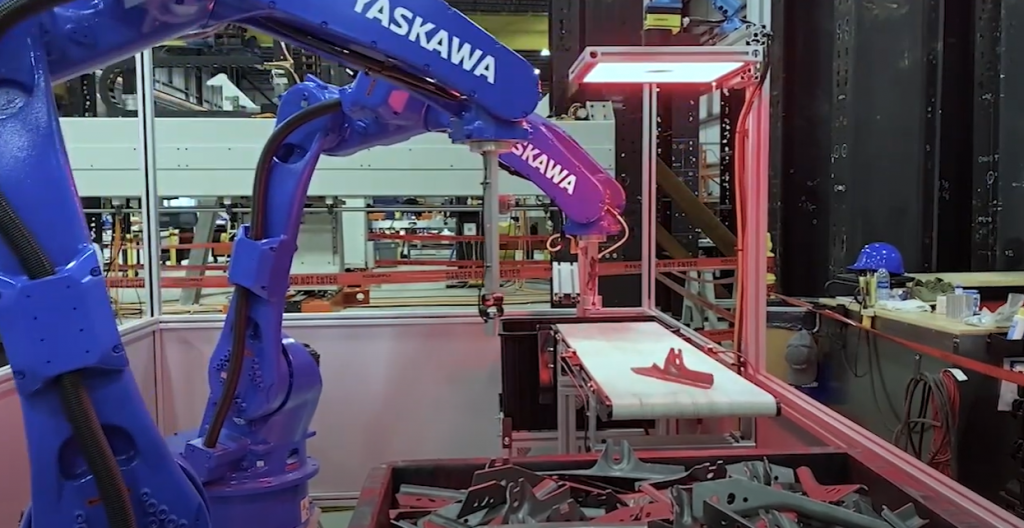

Linear Automation specializes in providing comprehensive automation upgrades and retrofits, breathing new life into existing systems while enhancing efficiency and functionality. Leveraging cutting-edge technologies and expertise, Linear Automation assesses the specific needs and goals of each project, offering tailored solutions to modernize outdated equipment and processes. Moreover, by retrofitting existing infrastructure with state-of-the-art components and software, Linear Automation enables businesses to stay competitive in rapidly evolving industries, unlocking new levels of productivity and cost-effectiveness without the need for full-scale replacements.

UPGRADES & RETROFITS

Linear Automation specializes in providing comprehensive automation upgrades and retrofits, breathing new life into existing systems while enhancing efficiency and functionality. Leveraging cutting-edge technologies and expertise, Linear Automation assesses the specific needs and goals of each project, offering tailored solutions to modernize outdated equipment and processes. Moreover, by retrofitting existing infrastructure with state-of-the-art components and software, Linear Automation enables businesses to stay competitive in rapidly evolving industries, unlocking new levels of productivity and cost-effectiveness without the need for full-scale replacements.

UPGRADES & RETROFITS

Linear Automation specializes in providing comprehensive automation upgrades and retrofits, breathing new life into existing systems while enhancing efficiency and functionality. Leveraging cutting-edge technologies and expertise, Linear Automation assesses the specific needs and goals of each project, offering tailored solutions to modernize outdated equipment and processes. Moreover, by retrofitting existing infrastructure with state-of-the-art components and software, Linear Automation enables businesses to stay competitive in rapidly evolving industries, unlocking new levels of productivity and cost-effectiveness without the need for full-scale replacements.

TRANSFER & DE-STACKING SYSTEM UPGRADES

LTA supplies 2 levels of control system upgrades for all transfer systems from any OEM:

CONTROLLER UPGRADES

FULL CONTROL SYSTEM UPGRADES

TRANSFER & DE-STACKING SYSTEM UPGRADES

LTA supplies 2 levels of control system upgrades for all transfer systems from any OEM:

CONTROLLER UPGRADES