AUTO-STACKING & RACKING

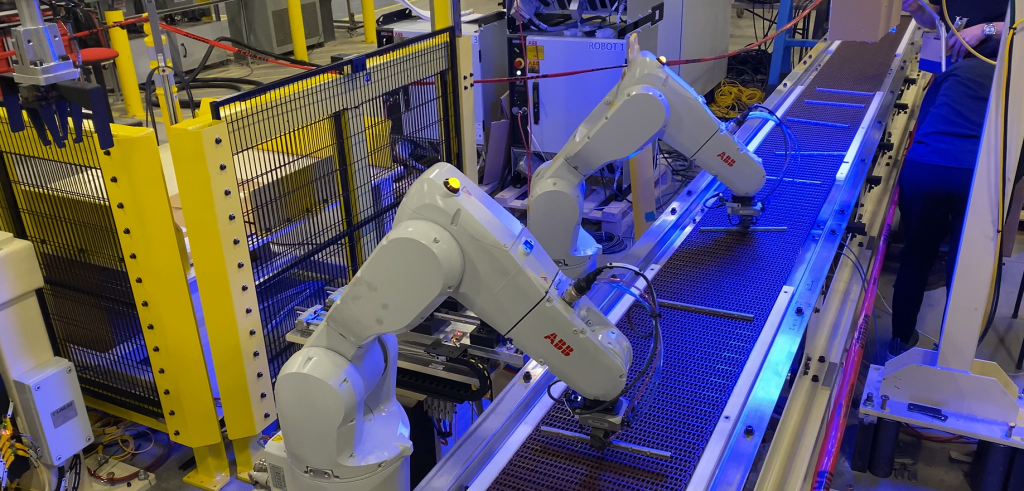

Linear Automation offers Auto-Stacking Solutions for a magnitude of metal-stamping processes. Robotic integration allows for quick and effective stacking in the press room, designed specifically for your needs.

System Configurations & Options

- In-line or t-style

- Elevated methods

AUTO-STACKING & RACKING

Linear Automation offers auto-stacking solutions for a magnitude of metal-stamping processes. Robotic integration allows for quick and effective stacking in the press room, designed specifically for your needs.

System Configurations & Options

- In-line or t-style

- Elevated methods

AUTO-STACKING & RACKING

Linear Automation offers auto-stacking solutions for a magnitude of metal-stamping processes. Robotic integration allows for quick and effective stacking in the press room, designed specifically for your needs.

System Configurations & Options

- In-line or t-style

- Elevated methods

Part Exit Systems

Linear offers a variety of part exit strategies for end-of-line solutions. Strategies include shuttle systems, robotics, high-speed unloaders, escapement chutes, and conveyors. Conveyors can be fixed, telescoping over bolster, shifting, tilting, single-lane, and multi-lane (with automatic adjustments).

Part Handling Systems

End-of-line part handling systems can be designed to fit the specific needs of the customer and part. Systems can be manual or robotic, and can also be designed as a pick-and-place.

Part Exit Systems

Linear offers a variety of part exit strategies for end-of-line solutions. Strategies include shuttle systems, robotics, high-speed unloaders, escapement chutes, and conveyors. Conveyors can be fixed, telescoping over bolster, shifting, tilting, single-lane, and multi-lane (with automatic adjustments).

Part Handling Systems

End-of-line part handling systems can be designed to fit the specific needs of the customer and part. Systems can be manual or robotic, and can also be designed as a pick-and-place.

Part Exit Systems

Linear offers a variety of part exit strategies for end-of-line solutions. Strategies include shuttle systems, robotics, high-speed unloaders, escapement chutes, and conveyors. Conveyors can be fixed, telescoping over bolster, shifting, tilting, single-lane, and multi-lane (with automatic adjustments).

Part Handling Systems

End-of-line part handling systems can be designed to fit the specific needs of the customer and part. Systems can be manual or robotic, and can also be designed as a pick-and-place.