COMPREHENSIVE TURNKEY STAMPING CELLS FROM A SINGLE SOURCE

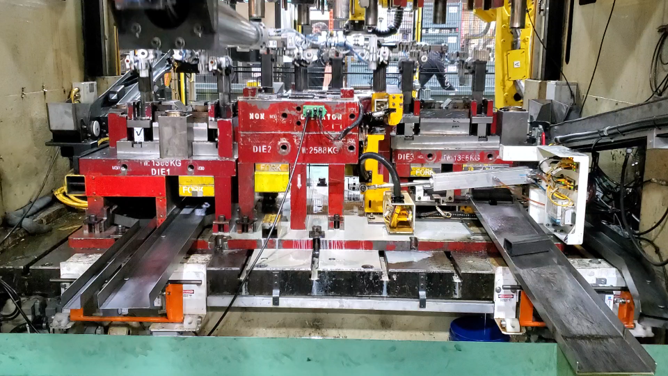

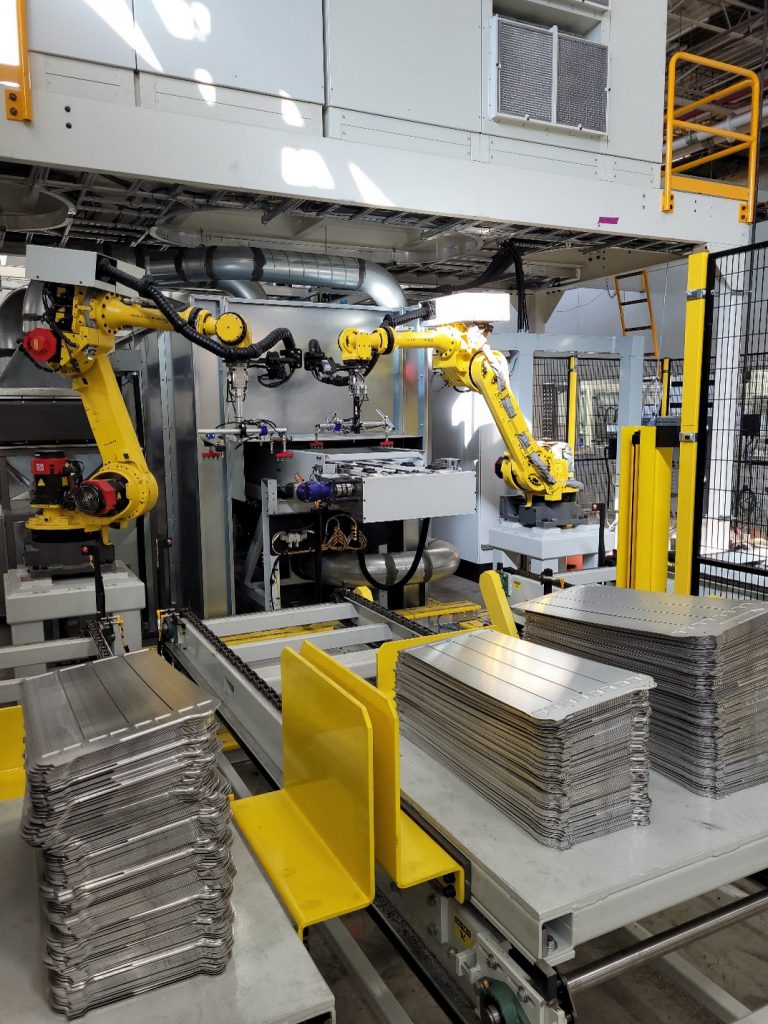

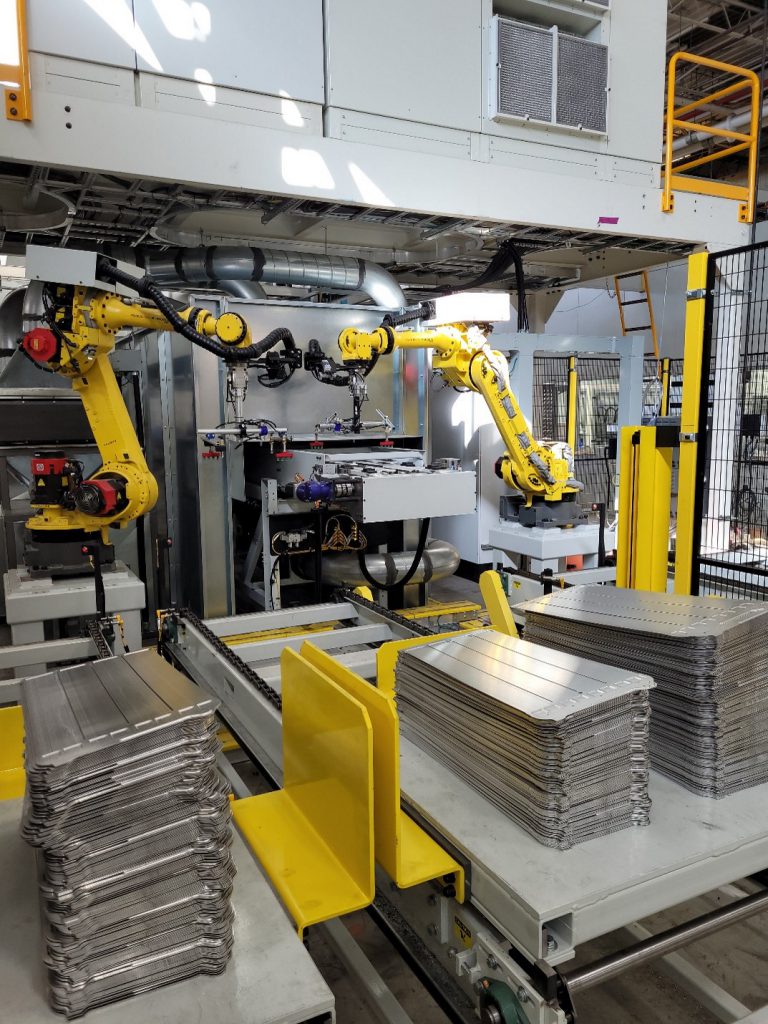

In today’s market, customers increasingly prefer to purchase complete stamping cells from a single provider rather than sourcing individual components from multiple vendors. Recognizing that automation is often the key factor in meeting line output requirements, many customers turn to Linear for turnkey solutions. At Linear, we offer a comprehensive range of products, including presses, coil feeders, line guarding, die change automation, finger tooling, light curtains, and more. Our expertise in project management ensures the success of these turnkey projects, making us the go-to source for all your press transfer automation needs.

ADAPT TO YOUR CHANGING NEEDS

In today’s market, many customers prefer to procure entire stamping cells from one source rather than buying individual pieces from multiple vendors. After realizing that automation is quite often the critical component in the line’s overall output requirements many customers have looked to Linear as a turnkey source. Presses, coil feeders, line guarding, die change automation, finger tooling, light curtains, etc. can all be sourced through Linear. Project management is the key to the success of these turnkey projects and is an area that Linear excels at.

ADAPT TO YOUR CHANGING NEEDS

In today’s market, many customers prefer to procure entire stamping cells from one source rather than buying individual pieces from multiple vendors. After realizing that automation is quite often the critical component in the line’s overall output requirements many customers have looked to Linear as a turnkey source. Presses, coil feeders, line guarding, die change automation, finger tooling, light curtains, etc. can all be sourced through Linear. Project management is the key to the success of these turnkey projects and is an area that Linear excels at.

ADAPT TO YOUR CHANGING NEEDS

In today’s market, many customers prefer to procure entire stamping cells from one source rather than buying individual pieces from multiple vendors. After realizing that automation is quite often the critical component in the line’s overall output requirements many customers have looked to Linear as a turnkey source. Presses, coil feeders, line guarding, die change automation, finger tooling, light curtains, etc. can all be sourced through Linear. Project management is the key to the success of these turnkey projects and is an area that Linear excels at.

IN-HOUSE CAPABILITIES

IN-HOUSE CAPABILITIES

IN-HOUSE CAPABILITIES

Process Engineering & Project Management

Mechanical & Electrical Engineering

Preventative Maintenance Programs

Robotic Programming

Mechanical & Electrical Manufacturing & Assembly

Global Installations

Warranty Support

Technical Service

PLC Controls

Optimize Entire Process Into Customer’s Production Flow

System Upgrades

Process Engineering & Project Management

Mechanical & Electrical Engineering

Preventative Maintenance Programs

Robotic Programming

Mechanical & Electrical Manufacturing & Assembly

Global Installations

Warranty Support

Technical Service

PLC Controls

Optimize Entire Process Into Customer’s Production Flow

System Upgrades